The quality of wire blending has a crucial impact on the frequency of wire breakage in weaving machines.

.jpg)

Tip 1: According to the flat width of the multiple threads to be merged, loosen the bolt circled in Figure 1, adjust the groove width of guide wheel 3 (position 2 in Figure 1), and lock the bolt after adjustment. Rotate the adjusting screw of the guide wheel in Figure 1 (position 1 in Figure 1) to adjust the position of the wire arrangement. Based on the actual wire arrangement effect multiple times, take the median (note: because plastic wire rollers are used, there may be some deformation), and then tighten the screw to clamp the adjusting screw of the guide wheel.

Tip 2: Wrap the wire significantly before merging (as shown in Figure 2), so that when there is no wire, the lower ingot can be placed more at once, causing the lower ingot parking lever to hit the brake switch, achieving the goal of early shutdown. For users who need to weave thicker diameters and multiple threads, and do not have the option to install an empty axis detection function when purchasing a weaving machine, this method can be considered to improve the weaving quality.

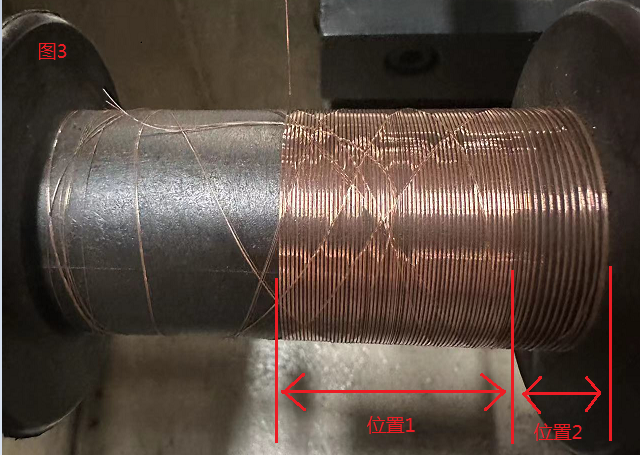

Tip 3: Adjust the width of the ribbon cable. In theory, the width of the wire arrangement is the most ideal state, with the minimum error in the length of the resulting wire. Due to factors such as shape errors, plastic deformation errors, and wire accuracy errors in reality, it is necessary to leave gaps between the threads to accommodate errors. In general, the width of the cable arrangement is, which can cover the entire wire winding core by arranging two layers back and forth (as shown in position 1 in Figure 3). In situations where the surface of the silk thread is rough and fragile, in order to reduce the friction area between the silk threads, it is recommended to adjust the width of the wire arrangement to three layers to cover the entire winding core (as shown in position 2 in Figure 3).

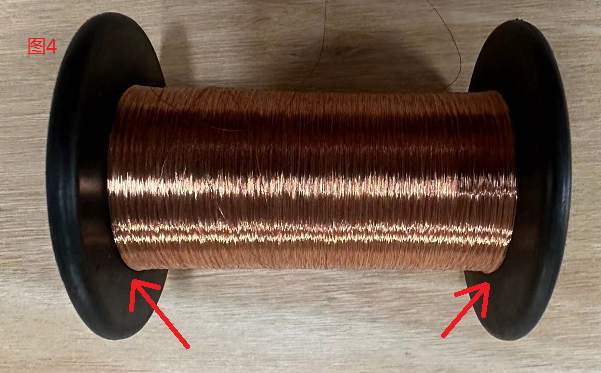

Tip 4: Due to the deformation caused by force on the plastic wire winding roller, the roller will expand towards both ends when the thread is full. So at the beginning, we merged the wires and adjusted the width of the ribbon to slightly convex at both ends (as shown by the arrow in Figure 4). When the thread is full, it will be laid flat, so there will be no concavity at both ends, causing wire jamming. (Note: The key is slight convexity. If there are more protrusions at both ends after merging, it will cause the thread to loosen.)

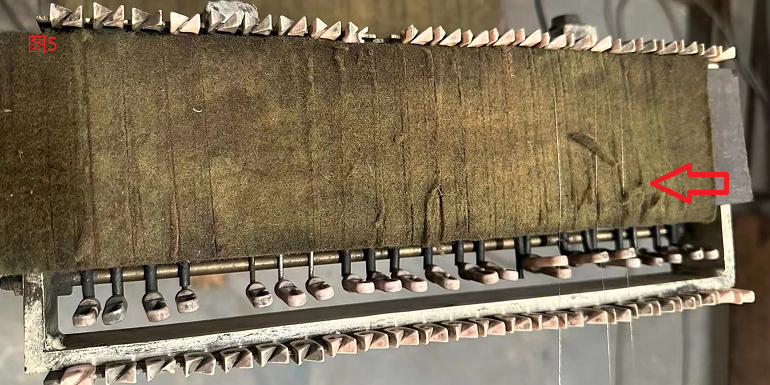

Tip 5: When the surface of the woven silk thread is rough and fragile. As shown in Figure 5, on the wire breakage protection frame, two wool blankets can be added with white mineral oil to clamp the silk thread, making the silk thread stick together and lubricating the surface of the silk thread, thereby enhancing the tensile strength of the silk thread and reducing roughness. If you cannot buy white mineral oil or wool blankets in the surrounding area, you can choose to shop online.

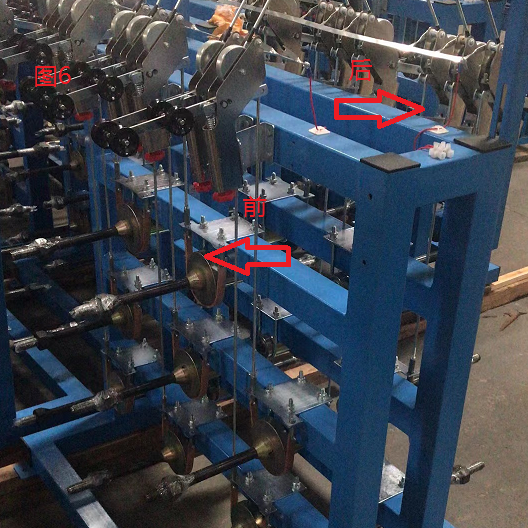

Tip 6: The cable reel in the back of the cable rack needs to go through an additional guide wheel, and the cable angle is also different from the front. To reduce the difference in thread length on the same parallel reel, it is recommended to choose the same direction of the winding axis for all threads on the same parallel reel (i.e., for the same parallel reel, either all in the front row or all in the back row).

.png)